-

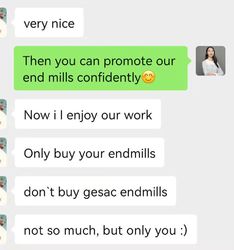

Customer BNow I enjoy our work. Only buy your end mills. Not so much, but only you.

Customer BNow I enjoy our work. Only buy your end mills. Not so much, but only you. -

Customer RToday I tested 50HRC 3 flutes end mill for aluminum. It was very very good. Cuts very good. It barely makes a sound.If you stop watching the machine, you cannot say it is cutting.

Customer RToday I tested 50HRC 3 flutes end mill for aluminum. It was very very good. Cuts very good. It barely makes a sound.If you stop watching the machine, you cannot say it is cutting.

1/2" 7 Flutes Chip Splitter Endmill For High Efficiency Milling Stainless Steel

| Name | 7 Flutes Chip Splitter End Mills | Type | Customized |

|---|---|---|---|

| Size | Customized | Coating | AlTiCrN Coating |

| Material | GU25UF Carbide Rod | Suitable For | Stainless Steel, And Heat-resistant Superalloys Such As 17-4PH, Inconel And Titanium. |

| Flute Type | Spiral Flute | Inch Or Millimeter | Millimeter |

| Variable Pitch | Yes | Variable Helix | No |

| Highlight | 7 Flutes Chip Splitter Endmill,1/2in Chip Splitter Endmill,HRC50 Custom End Mill |

||

1/2" 7 Flutes Chip Splitter Endmill for High Efficiency Milling steel and stainless steel

It helps machinists cut faster and longer by enhancing the ability to flush or blow away stringy chips from

deep axial cuts, without forming clumps of intertwined swarf. This is very important to avoid re-cutting of chips,

which could damage the cutting edges and shorten tool life, Additionally, the ability to rough and finish with the

same tool provides great benefit in cycle time and inventory management, both in the tool crib and the machine’s carousel.

The 7-flute chip splitter excels in machining stainless steel, and heat-resistant superalloys such as 17-4PH, inconel and titanium.

| Product name | 7 Flutes Chip Splitter End Mills |

| Feature | High efficiency for side milling |

| Suitable for | Steel, stainless steel, 17-4PH, inconel and titanium |

| Machine type | CNC milling machine |

| Flutes | 7 |

| Coating | Customized/AlTiCrN |

| Helix | Customized |

Carbide Raw Material Introduction

| End mill grade | Carbide rod | Grain size | HRA | Application |

| HRC50 | YG10X | 0.6μm | 91.8 |

Aluminum, iron, low alloy steel, general steel under hardness HRC45 |

| HRC55 | WF25 | 0.6μm | 92.2 | Cast Iron, Alloy Steel, General steel under hardness HRC50 |

| HRC60 | GU25UF | 0.4μm | 92.5 | Super Alloy Steel, Stainless Steel, Titanium, Inconel, Hardened Steel under hardness HRC55 |

| HRC65 | GU092 | 0.2μm | 93.5 | Alloy Steel, Hardened Steel under hardness HRC62 |

Coating Introduction

| Coating name | Color | Thickness | Hardness | Friction | The Max ℃ |

| AlTiN | Black | 1.5-3 | 3300 | 0.4 | 900 |

| AlTiSiN | Copper | 1.5-3 | 3500 | 0.35 | 1000 |

| TiAlN | Dark Violet | 1-3 | 3000 | 0.4 | 800 |

| Blue Nano | Blue | 2-4 | 3200 | 0.45 | 1000 |

| AlCrN | Dark grey | 1.5-3 | 3500 | 0.3 | 1250 |

| DLC | Black | 1-3 | 1800 | 0.1 | 350 |

| Diamond | Black | 2-12 | 10000 | 0.02-0.1 | 650 |

| Coating also can be customized according to your requirement. |

![]()

FAQ

1. Are you a manufacturer or trading company?

We are a professional manufacturer of carbide tools which established in 2011.

2. Which CNC grinding machine do you use?

All of our carbide tools are produced by ANCA & grinding machines.

3. Which shipping method do you usually use?

We usually send goods by express like FedEx, UPS, DHL, TNT, EMS, ETC.

For large amount, we can send by air or by sea.

We also can send products to your forwarder in China.

4. How about the delivery time?

For stock items, we can dispatch within 2 business days after receiving payment.

For the out-of-stock items, it depends on the quantity.

Usually is around 5-7 business days.

5. Which payment methods do you accept?

We accept T/T, Trade Assurance Order on Alibaba(credit card), PayPal, etc.

CNY is also acceptable.

6. What kind of grinding wheels do you use?

We are using WINTER brand grinding wheels.

They are imported from Germany.

The High-quality grinding wheel is also important for the quality of carbide tools.

7. Can you do OEM?

Yes, we can engrave your logo on the tool's shank and make customized stickers.